当前位置:网站首页>Before implementing MES management system, these three questions to consider

Before implementing MES management system, these three questions to consider

2022-08-10 20:58:00 【Deep Blue Easy Network】

MES management system is an extremely complex system. Enterprises should choose the corresponding functional modules and the priority of going online according to their own needs.

MES production management system is used well, which is conducive to the transformation of enterprises from experience management to data management, helping enterprises to make better decisions and be more sensitiveIdentify problems, analyze problems, and solve problems.

Of course, in different industries, there are certain differences in the requirements of MES production management system.To implement an MES management system, an enterprise must also have a deep understanding of its own needs and current development in order to find the right solution for the MES management system.To implement MES management system, these three aspects need to be considered:

1, Analyze Manufacturing Execution Capability

The ultimate goal of MES production management system is to improve the ability and level of manufacturing execution.Therefore, before implementing an MES management system, the first issue is to evaluate the current manufacturing execution capability.

From the perspectives of manufacturing strategy, manufacturing quality, supply chain coordination, information collection, performance management and improvement, manufacturing and IT infrastructure, etc.The maturity level of manufacturing execution capability is divided into five grades: inferior, fair, good, excellent, and future pursuit goals.

2, select MESfunction modules of the management system

The most important module in the MES system: the core of the production operation management module, namely production planning, statistics and scheduling.

The basis of production operation is equipment and its operation, so the equipment management module and data acquisition and storage (real-time database) should also be part of the MES system.Basic module.

Generally, there are also product quality management modules, cost management modules, material balance and warehouse management modules, etc.

At present, with the intensification and refinement of management, new information technology and software have increased the new functional requirements of MES.

3, do a good job of "three integration"

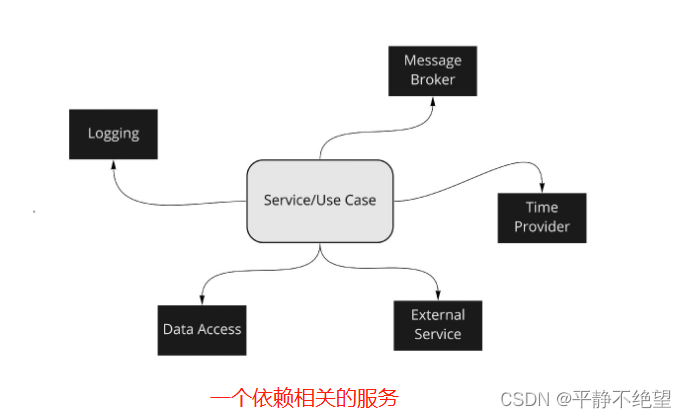

As an advanced production management technology at the workshop level, MES management system has the ability of integration, flexibility, openness, self-organization, adaptation and reconstructionIt plays an important role in the optimal operation and agility of the manufacturing process on the shop floor.

Therefore, it is necessary to do a good job in the integration of various modules of MES, the integration of MES and PCS/ERP, and the integration of internal and external enterprises.

"Made in China 2025" clearly proposes to promote the intelligentization of the manufacturing process, and promote the simulation optimization, digital control, and status information of the manufacturing process through the construction of smart factories.Real-time monitoring and adaptive control to achieve intelligent management and control of the entire process.

The application of MES management bear is one of the important informatization means for manufacturing enterprises to promote intelligent manufacturing and move towards "Made in China 2025". It can even be said that, MES is the way to go.

边栏推荐

- Water-soluble alloy quantum dot nanozymes|CuMoS nanozymes|porous silicon-based Pt(Au) nanozymes|[email protected] nanomimetic e

- npm warn config global `--global`, `--local` are deprecated. use `--location=global` instead.

- [Golang]如何优雅管理系统中的几十个UDF(API)

- 2020 ICPC Shanghai Site G

- Public Key Retrieval is not allowed(不允许公钥检索)【解决办法】

- 二级指针的简单理解

- 2021DASCTF实战精英夏令营暨DASCTF July X CBCTF 4th

- npm WARN config global `--global`, `--local` are deprecated. Use `--location=global` instead.

- 论配置化系统的配置

- 饿了么-机构树单选

猜你喜欢

随机推荐

2021 CybricsCTF

Date picker component (restrict year to set only displayed months)

sklearn 笔记 TSNE

关于 NFT 版权保护的争议

每日一R「03」Borrow 语义与引用

Tf ferritin particles contain cisplatin / oxaliplatin / doxorubicin / methotrexate MTX / paclitaxel PTX and other drugs

哈工大软件构造Lab3(2022)

【ACM】dp专场训练

双 TL431 级联振荡器

[CNN] Brush SOTA's trick

爬虫基本原理介绍、实现以及问题解决

2021DASCTF实战精英夏令营暨DASCTF July X CBCTF 4th

如何提交一个PR?【OpenHarmony成长计划】【OpenHarmony开源社区】

mysql性能监控与执行计划

实施MES管理系统前,这三个问题要考虑好

MySQL数据库的主从复制部署详解

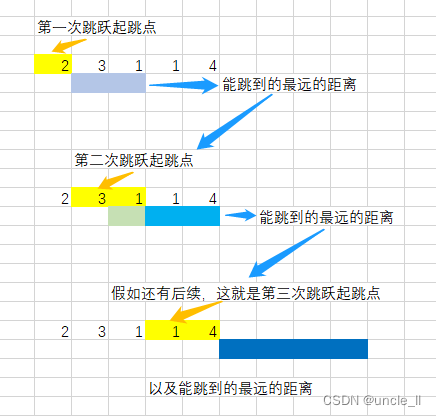

leetcode:45. 跳跃游戏II

转铁蛋白(Tf)修饰去氢骆驼蓬碱磁纳米脂质体/香豆素-6脂质体/多柔比星脂质体

大小端的理解以及宏定义实现的理解

这些mysql基础命令、基础知识还记得吗?(面试,学习,复习都可以)一万三千字总结

![[SWPUCTF 2021 新生赛] web](/img/e9/07e7db7ddf8328589a078e98fd46ad.png)

![[mysql] 深入分析MySQL版本控制MVCC规则](/img/16/e28641c355d941fda50a6e8b7911ee.png)