当前位置:网站首页>The introduction of lean management needs to achieve these nine points in advance

The introduction of lean management needs to achieve these nine points in advance

2022-04-23 05:16:00 【Fried broad beans eat bouncing beans】

Lean management is also called lean production , It was first summarized by American production management experts from the management practice of Toyota , It is a scientific management concept proved by practice , And gradually more and more enterprises learn and learn from . 1996 year ,James P.Womack and Daniel T.Jones stay 《 Machines that change the world 》 On the basis of , Published 《 Lean thinking 》 A Book , The book theorizes lean production , The principles and methods of lean are systematically described , Formed a lean ideological system .

With the learning upsurge set off by lean management , Many enterprises are also engaged in the transformation of Lean Management . Many enterprises have solved many problems perplexing themselves through lean management , It has increased production and efficiency , Established a lean management system suitable for their respective enterprises , But there are also many unsuccessful explorations . The reason is , It is usually because the core of lean management is not combined with the enterprise's own development . Understand lean management only :“5s、 Kanban 、 Anton (Andon) System 、JIT (Just In Time)、 Leveling ” And a series of management tools , So these tools can be applied to the daily management of their respective enterprises .

Enterprises want to introduce lean management , You need to first understand the concept of Lean Management . And make it clear that its core is : Authors efficiency , Reduce waste , Finally, improve the efficiency of the enterprise . in general , When enterprises use lean management , We must first understand and agree with the following nine points about the basis of Lean Management , So as to help the lean management model get more recognition in enterprises , Finally achieve a better landing .

One 、 Lean management requires long-term persistence

Lean management requires a long-term manifestation process , In the early or middle stage of implementing lean management in enterprises , The profit or benefit of the enterprise has not increased significantly , There may even be short-term stagnation . But to achieve lean production , Enterprises need to set lean management as the goal of giving priority to the short-term growth of enterprises .

Two 、 Establish a cycle 、 Uninterrupted workflow

The process of an enterprise needs continuous iteration 、 improve , To adapt to the changing market environment , Through lean management , Guide managers to pay more attention to process , By establishing a loop 、 Continuous process , The production and management of the enterprise will run at a high speed , It is possible to minimize the time of idle waiting or waiting to cooperate with other work in the production process .

3、 ... and 、 Transformation of the original production mode

Lean management thought believes that , Corporate waste is everywhere , There will be tangible and intangible waste in the production process , These can be avoided through lean management mode , Carefully analyze customer needs , Through the needs of customers , Allocate all links of production , The final supply of products in line with customer demand . in fact , In the process of software development , Waste can also be seen everywhere , Even more amazing , These wastes are mainly reflected in :

1. Additional feature settings

In the traditional software development process , Will intentionally or unintentionally create a large number of functions that people don't need , And these too many functional features will make the system redundant , It will also increase the cost of the team .

2. stock

One of the seven major wastes in traditional manufacturing is “ stock ”, This also exists in software development , The common phenomenon is that the completed functions have to wait for a long time to be tested , The tested functions will wait for a long time before being accepted by the customer , All of these are in the process of software development , They are the second biggest waste in software development .

3. Over handling

Overhandling is not just in software requirements , It still exists in the code . Many programmers or R & D teams , Will do a lot in the code “ preventive ” Work , To deal with possible problems . On the one hand, this approach increases the unnecessary complexity of the program , On the other hand, if “ Possible ” It never happened , This code becomes a waste .

4. Information transmission

The situation that development teams often face is that it is difficult to find customers to communicate and confirm their needs , Or have to spend a lot of time and energy looking for all kinds of needed information , The time the team spent looking for information , Does not directly create the value of software , So it can also be classified as a waste .

5. Software defect

In the process of software development , Find out Bug、 The report Bug、 location Bug、 Repair Bug、 verification Bug We have to put manpower into it 、 Material force and time , This is also an invisible waste in the process of software development .

6. wait for

A software from research and development to delivery , A long or short waiting time in between . Whether it's the customer's waiting , Or wait for each other within the development team , Are worthless things . meanwhile , Waiting will also delay the exposure and resolution of the problem , Inevitably lead to waste .

To avoid this waste , Let software development also “ Lean ” get up , Enterprises and R & D teams need to change the way they work into ” PULL “ Production by production , Introduce Kanban Management Visualization for continuous pulling , Try to reduce inventory , Improve R & D efficiency 、 Identify R & D needs and avoid over design , Reduce... As much as possible Bug Bring unnecessary waste . Encourage full communication between teams 、 Reduce communication during R & D 、 Waiting time , Let production management circulate efficiently . However , Any change is not easy . Before implementing lean management , We need to have the determination to change production .

Four 、 Establish the courage to pause immediately to solve the problem

A culture that values quality management from the beginning . On Toyota's production line , There is a set called Andon System ( Anton system ) Line stopping device for , Any worker can because of quality 、 Safety and other issues , Stop the production line immediately . Lean management believes that , Establish an immediate pause to solve the problem , This ensures that the problem is stopped when it is found , Ensure product quality .

5、 ... and 、 Develop standardized workflow

Lean management encourages all departments to do routine work in their work , Made by “ Standardization work instruction ” And so on , And constantly optimize it in combination with daily work , improve , In order to improve work efficiency , It is more conducive to quickly train new people for the company and department .

6、 ... and 、 Try to use visual management

The purpose of visualization is to tell employees what to focus on , For example, safety. 、 quality 、 efficiency 、 cost 、 staff 、 Culture and so on . In fact, the content that can be presented is more than that , Enterprises and managers can put any important information in production management . Visual display through electronic Kanban or whiteboard . In this way, the idea advocated by the company 、 Work objectives 、 A series of problems such as job requirements , Present clearly every day . You can also use A3 Methods of data management .A3 Data is a standard method and core communication tool commonly used by Toyota in lean management . The specific implementation method : Use one A3 Paper summarizes a problem , Solve the problem 8 A step ( Clarify the problem 、 Break down the problem 、 Set a goal 、 Grasp the truth 、 Develop countermeasures 、 The implementation of 、 Evaluation results and process 、 Consolidate results ) Summarize , Make the problems that need to be solved A3 Information , Through the discussion between the leader and the team , Find a solution quickly .

7、 ... and 、 Promote lean thinking learning

Implement lean management in enterprises , We should not push forward blindly , We need to cultivate teams and individuals who can accept and recognize the concept of Lean Management , So that the values of lean management can be effectively implemented . And through regular learning and training, constantly strengthen , Teach employees how to achieve efficient cooperation between teams in a lean way of thinking , Work with the company to achieve business objectives .

8、 ... and 、 Determination to continuously improve

Naiichi Ono once proposed “ No problem is the biggest problem ”. In Toyota's lean management ,PDCA It's a continuous rolling upward cycle . Break the status quo , Continuous improvement , Set goals , Achieve the goal , If the result deviates from the goal , We need to review the problem , adopt PDCA Cycle management , Help the company continuously explore the rising space .

Nine 、“ people oriented ” The values of

Toyota's lean management model , From its corporate values and management philosophy , Toyota's basic idea of people is “ The so-called respect for human nature , Is to keep people from doing ineffective work , Improve people's value ”. Lean management also advocates “ The spirit of challenge 、 Keep improving 、 Teamwork and respect for others ” The humanistic spirit of . Therefore, the implementation of lean management requires enterprises to “ Respect for the individual 、 people oriented ” As the dominant belief , Give full play to each employee's ability and personal value .

in summary , Learn and implement lean management thinking , Enterprises and teams need to do their homework in advance , Lean not only in tools and management methods , It also needs to be at the level of the company's values , Complete the transformation of lean thinking . Build lean culture and lean management system . Lay a solid foundation for the lean management of the company 、 Be prepared .

版权声明

本文为[Fried broad beans eat bouncing beans]所创,转载请带上原文链接,感谢

https://yzsam.com/2022/04/202204230510215909.html

边栏推荐

- Use the built-in function of win to transfer files between two computers in the same LAN (the speed is the same as that between local disks)

- A trinomial expression that causes a null pointer

- Summary of MySQL knowledge points

- 学习笔记:Unity CustomSRP-12-HDR

- 多线程基本概念(并发与并行、线程与进程)和入门案例

- Pandas to_ SQL function pit avoidance guide "with correct code to run"

- [untitled] kimpei kdboxpro's cool running lantern coexists with beauty and strength

- Collaboration future object and concurrent futures

- Semi synchronous replication of MariaDB

- MySQL slow query

猜你喜欢

工具在数字化转型中扮演了什么样的角色?

何时适合进行自动化测试?(下)

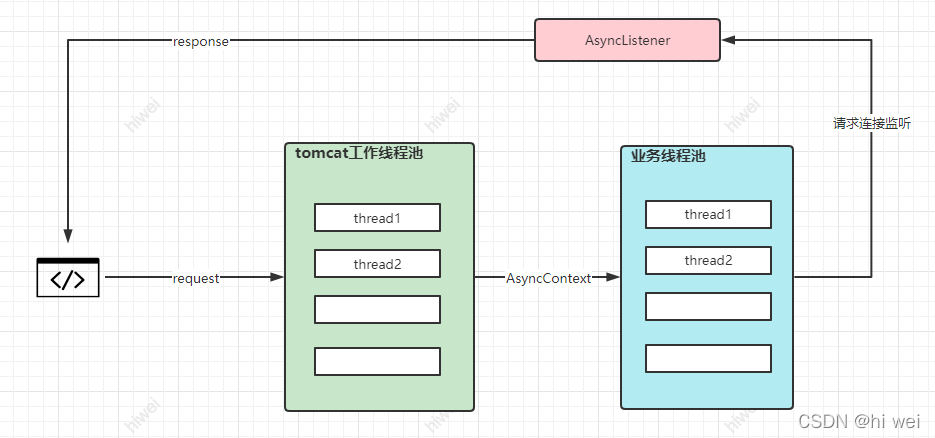

Servlet3 0 + event driven for high performance long polling

看板快速启动指南

2021-09-23

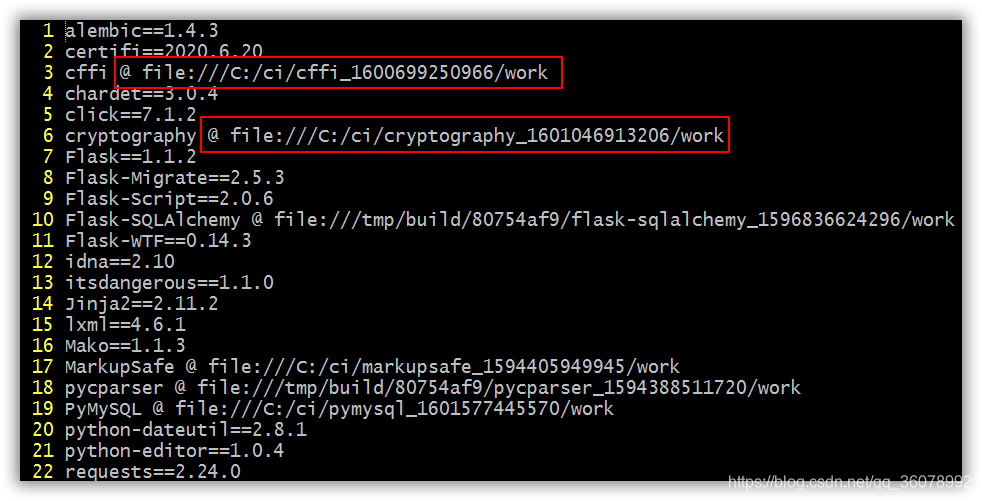

PIP free export with path (@ file: / / /) notes

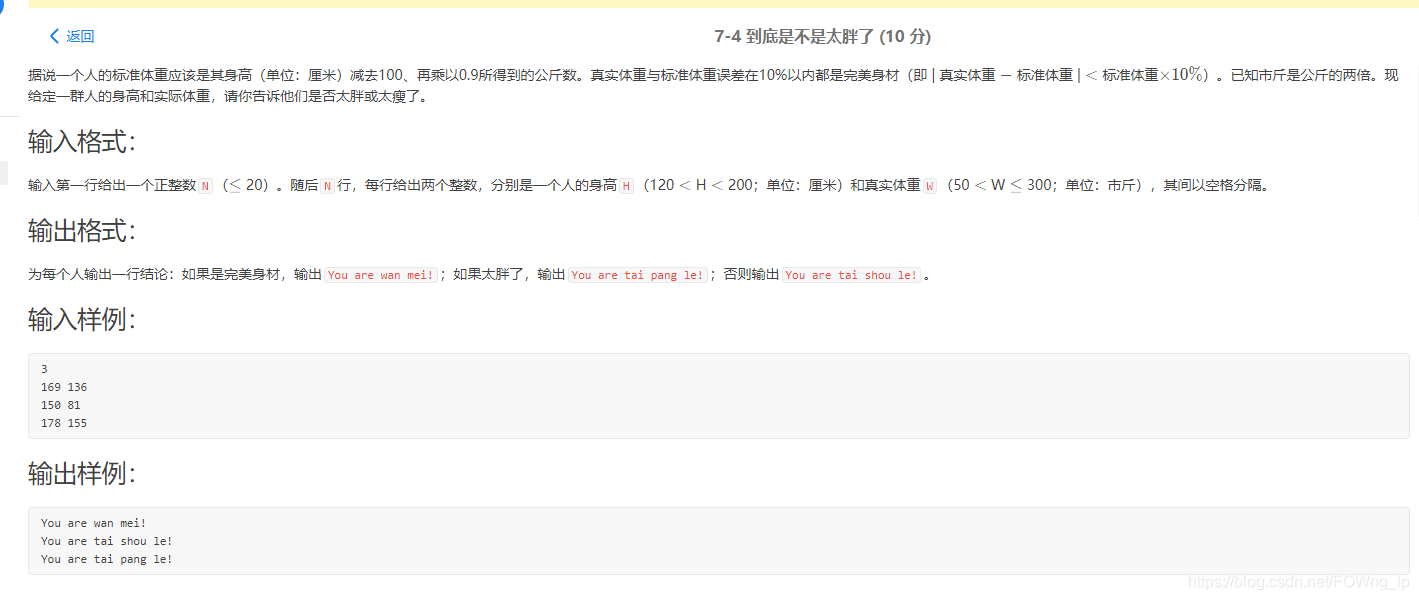

7-4 is it too fat (10 points) PTA

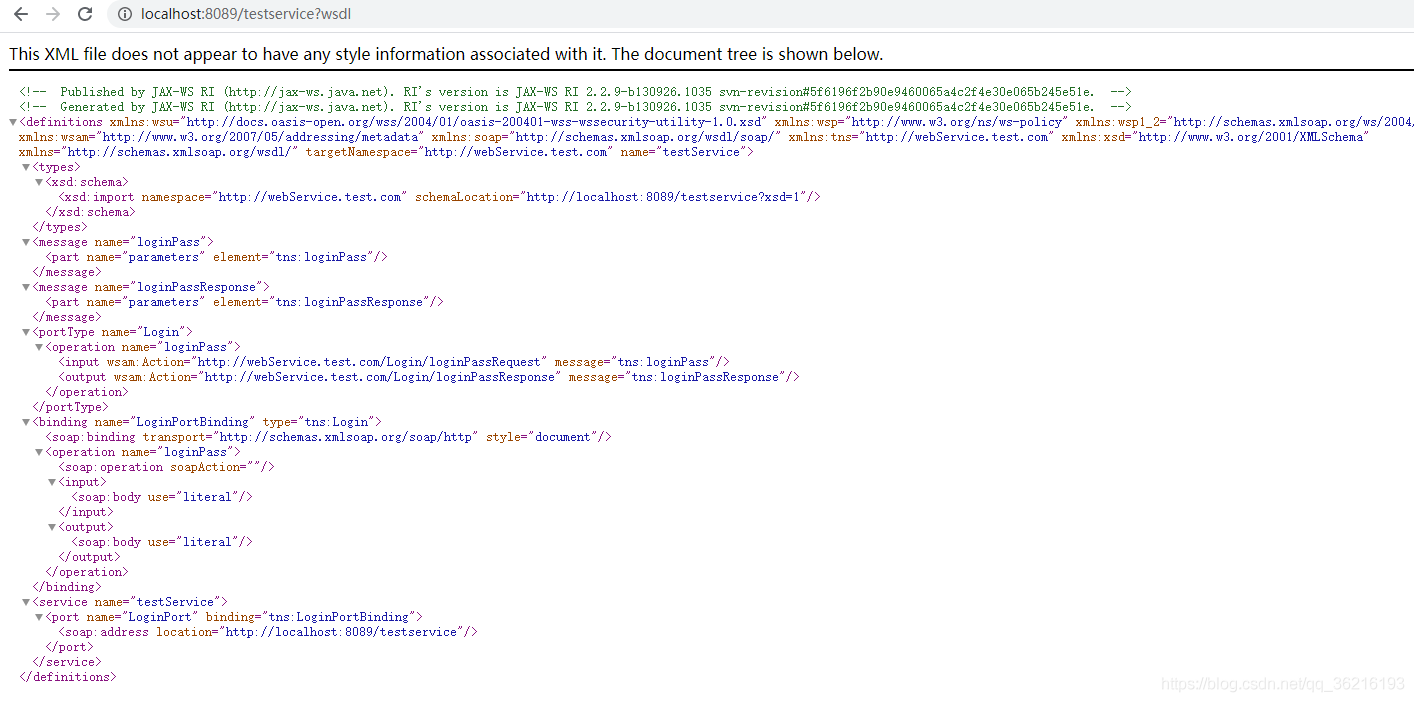

The WebService interface writes and publishes calls to the WebService interface (I)

Detailed explanation of concurrent topics

Basic theory of Flink

随机推荐

[2022 ICLR] Pyramid: low complexity pyramid attention for long range spatiotemporal sequence modeling and prediction

Golang memory escape

MFC实现资源单独Dll实现

何时适合进行自动化测试?(下)

JSP -- Introduction to JSP

如何在Word中添加漂亮的代码块 | 很全的方法整理和比较

How does PostgreSQL parse URLs

The WebService interface writes and publishes calls to the WebService interface (I)

Streamexecutionenvironment of Flink source code

Routing parameters

了解 DevOps,必读这十本书!

Locks and transactions in MySQL

多线程基本概念(并发与并行、线程与进程)和入门案例

Summary of MySQL knowledge points

Independent station operation | Facebook marketing artifact - chat robot manychat

Redis lost key and bigkey

2022年最热门的招聘技术技能是什么,您绝对想不到

The difference between static pipeline and dynamic pipeline

Collaboration future object and concurrent futures

开源规则引擎——ice:致力于解决灵活繁复的硬编码问题