当前位置:网站首页>Grbl learning (II)

Grbl learning (II)

2022-04-23 15:55:00 【Sola_ Ex】

GRBL Study

config.h file

You can know from the beginning of the file , This file is used to configure for different machines . Yes GRBL Come on , If the motherboard is replaced , Use 2560 or 128P If these chips , Ignore the configuration of this file directly . But I don't use this 、、

EEOROM Use default configuration after reset

#define DEFAULTS_GENERIC

Baud rate

#define BAUD_RATE 115200

The use of Arduino chip

#define CPU_MAP_ATMEGA328P // Arduino Uno CPU

in the light of GRBL The command parses characters

#define CMD_STATUS_REPORT '?'

#define CMD_FEED_HOLD '!'

#define CMD_CYCLE_START '~'

#define CMD_RESET 0x18 // ctrl-x.

#define CMD_SAFETY_DOOR '@'

The motor is locked when powered on ; This function seems strange , In fact, this is GRBL A protection function for laser engraving , Normal use GRBL When , After power on , Can't directly control XY The mobile , here GRBL Will send a prompt in the serial port , Let you unlock , And you need to send a X Of finger Make to G R B L , Explain lock after only can just often fuck do electric machine . too cheng in meet To police newspaper , also Meeting production raw On lock shape state , Same as sample yes send use X Give instructions to GRBL, The motor can be operated normally only after unlocking . An alarm was encountered in the process , It will also produce a locked state , Also use X Of finger Make to GRBL, Explain lock after only can just often fuck do electric machine . too cheng in meet To police newspaper , also Meeting production raw On lock shape state , Same as sample yes send use X This command can be used normally . After all, the power of the laser head is no joke ...

#define HOMING_INIT_LOCK

The control pin is here , in the light of CNC Only some

#define HOMING_CYCLE_0 (1<<Z_AXIS)

#define HOMING_CYCLE_1 ((1<<X_AXIS)|(1<<Y_AXIS))

The number of times the limit is touched when returning to zero

#define N_HOMING_LOCATE_CYCLE 1

GRBL in the light of CNC The floating point type of the display ( In real time, this is for 8 Floating point operation processing of bit single chip microcomputer , If replaced 32 Bit with floating point operation , You can optimize here )

#define N_DECIMAL_COORDVALUE_INCH 4

#define N_DECIMAL_COORDVALUE_MM 3

#define N_DECIMAL_RATEVALUE_INCH 1

#define N_DECIMAL_RATEVALUE_MM 0

#define N_DECIMAL_SETTINGVALUE 3

Coordinate information feedback , When disabled, only the last set of coordinate information can be obtained ( This should be used together with the upper computer )

#define MESSAGE_PROBE_COORDINATES

Safety delay time after safety switch switching

#define SAFETY_DOOR_SPINDLE_DELAY 4000

#define SAFETY_DOOR_COOLANT_DELAY 1000

Offset Set enable

#define TOOL_LENGTH_OFFSET_AXIS Z_AXIS

Variable spindle enable

#define VARIABLE_SPINDLE

belt S The order of ,S The latter is worth the scope , Such as M3 S255

#define SPINDLE_MAX_RPM 1000.0

#define SPINDLE_MIN_RPM 0.0

Minimum cross speed setting

#define MINIMUM_JUNCTION_SPEED 0.0 // (mm/min)

Minimum printing speed

#define MINIMUM_FEED_RATE 1.0 // (mm/min)

Radian correction value ( The setting of the value here is similar to GRBL Print related ,GRBL Algorithm for printing arcs )

#define N_ARC_CORRECTION 12

版权声明

本文为[Sola_ Ex]所创,转载请带上原文链接,感谢

https://yzsam.com/2022/04/202204231554163679.html

边栏推荐

- s16.基于镜像仓库一键安装containerd脚本

- 王启亨谈Web3.0与价值互联网“通证交换”

- volatile的含义以及用法

- Upgrade MySQL 5.1 to 5.610

- utils. Deprecated in35 may be cancelled due to upgrade. What should I do

- 时序模型:门控循环单元网络(GRU)

- 捡起MATLAB的第(4)天

- Timing model: gated cyclic unit network (Gru)

- Import address table analysis (calculated according to the library file name: number of imported functions, function serial number and function name)

- One brush 312 - simple repetition set - Sword finger offer 03 Duplicate number in array (E)

猜你喜欢

Spark 算子之distinct使用

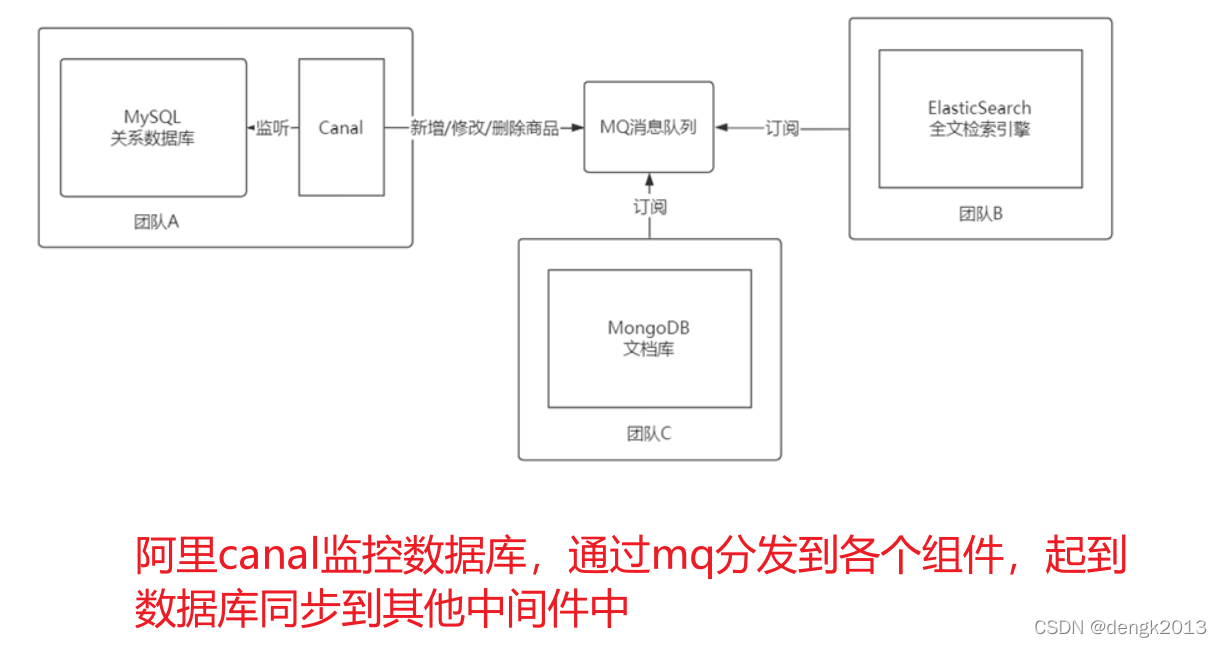

MySQL集群模式与应用场景

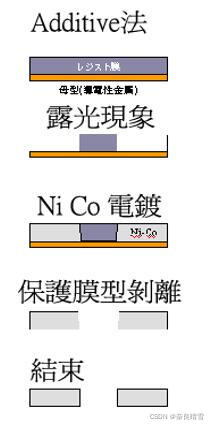

【现代电子装联期末复习要点】

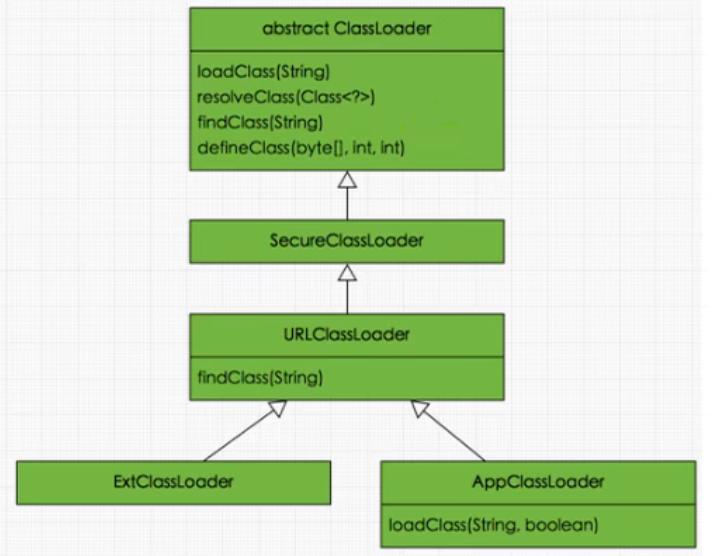

JVM - Chapter 2 - class loader subsystem

Unity shader learning

5分钟,把你的Excel变成在线数据库,神奇的魔方网表excel数据库

Import address table analysis (calculated according to the library file name: number of imported functions, function serial number and function name)

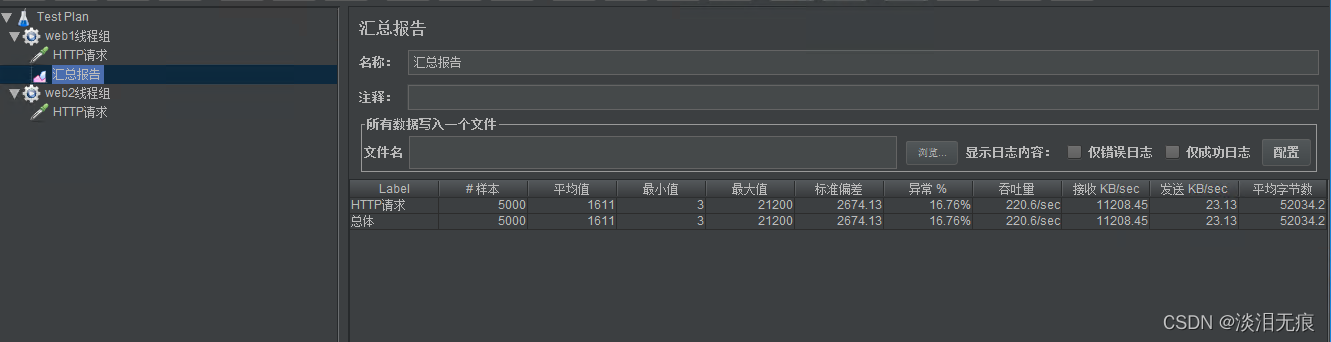

Website pressure measurement tools Apache AB, webbench, Apache jemeter

保姆级Anaconda安装教程

Tencent offer has been taken. Don't miss the 99 algorithm high-frequency interview questions. 80% of them are lost in the algorithm

随机推荐

Distinct use of spark operator

MetaLife与ESTV建立战略合作伙伴关系并任命其首席执行官Eric Yoon为顾问

Win11/10家庭版禁用Edge的inprivate浏览功能

One brush 313 sword finger offer 06 Print linked list from end to end (E)

5 minutes, turn your excel into an online database, the magic cube net table Excel database

VIM specifies the line comment and reconciliation comment

Upgrade MySQL 5.1 to 5.69

One brush 314 sword finger offer 09 Implement queue (E) with two stacks

负载均衡器

运维流程有多重要,听说一年能省下200万?

Spark 算子之交集、并集、差集

s16. One click installation of containerd script based on image warehouse

Intersection, union and difference sets of spark operators

The principle and common methods of multithreading and the difference between thread and runnable

GRBL学习(一)

ESP32_Arduino

How important is the operation and maintenance process? I heard it can save 2 million a year?

Spark 算子之distinct使用

Codejock Suite Pro v20. three

Go language, condition, loop, function