当前位置:网站首页>Model problems of stock in and stock out and inventory system

Model problems of stock in and stock out and inventory system

2022-04-23 17:14:00 【ZHZHK001】

My current idea is :

Scheme 1 ,1 Tables : Only stock in / stock out table

No inventory table , Inventory data is calculated in real time according to receipt / issue

The disadvantage is that there are a lot of stock in and stock out data , The amount of real-time inventory query data will be larger and larger

There are also problems with scheme 2

Option two ,2 Tables : An inventory statement + Warehouse in and out table , In and out of the warehouse ,2 Data update of two tables at the same time

There is no problem when the stock in record is added

The problem is :

The issue record is added ( In particular, add the previous delivery record )、

Out of stock 、 Modification and deletion of warehousing records

These circumstances will affect the rationality of all subsequent records , The amount of data processing is large

such as

A library 2022-02-10 Enter into 100

A library 2022-02-11 Enter into 10 When deleting , Next 2 This piece of data is invalid , Enter into 10 Change to in 6 ,2-13 Out 15 It doesn't work

A library 2022-02-12 Out 105

A library 2022-02-13 Out 15

Option three , Scheme 2 upgrade

2 Tables : An inventory statement + Warehouse in and out table , In and out of the warehouse ,2 Data update of two tables at the same time

Issue / receipt records can only be added but not deleted 、 Change ,【 Notes of receipt / issue records can be changed 】

If there is a problem , Add a record for today , Hedge against previous data

such as 2022-02-14【 today 】 Find out 2022-02-13A There are too many entries in the warehouse 100 individual

So the way to deal with it is :

2022-02-14【 today 】 Add a record 2022-02-14 A Warehouse out 100 individual Type selection hedging

The delivery process

Inventory query whether there is enough stock out ,

yes , An inventory statement update, Warehouse in and out table insert

no , Cancel operation

remarks : The quantity of record lines in the inventory table may be... During delivery 0

Warehousing process

An inventory statement A library B Whether the material has inventory records

yes , An inventory statement UPDAGE, Warehouse in and out table insert

all , An inventory statement insert, Warehouse in and out table insert

Option four , Scheme I upgrade

Issue / receipt records can only be added but not deleted 、 Change ,【 Notes of receipt / issue records can be changed 】

If there is a problem , Add a record for today , Hedge against previous data

such as 2022-02-14【 today 】 Find out 2022-02-13A There are too many entries in the warehouse 100 individual

So the way to deal with it is :

2022-02-14【 today 】 Add a record 2022-02-14 A Warehouse out 100 individual Type selection hedging

I don't know what other better model

At present, I personally prefer to use the model of scheme 3 , If anyone has a better model , Please advise

The data table structure is :

An inventory statement

id

Warehouse id

materiel id

Number

remarks

The creator

Creation time

Reviser

Modification time

Warehouse in and out table

id

fromid

toid

materiel id

Number

remarks

type 【 Out of stock 、 Put in storage 、 hedging 】

The creator

Creation time

Reviser

Modification time

Other fields such as order number

版权声明

本文为[ZHZHK001]所创,转载请带上原文链接,感谢

https://yzsam.com/2022/04/202204230553251144.html

边栏推荐

- VLAN高级技术,VLAN聚合,超级Super VLAN ,Sub VLAN

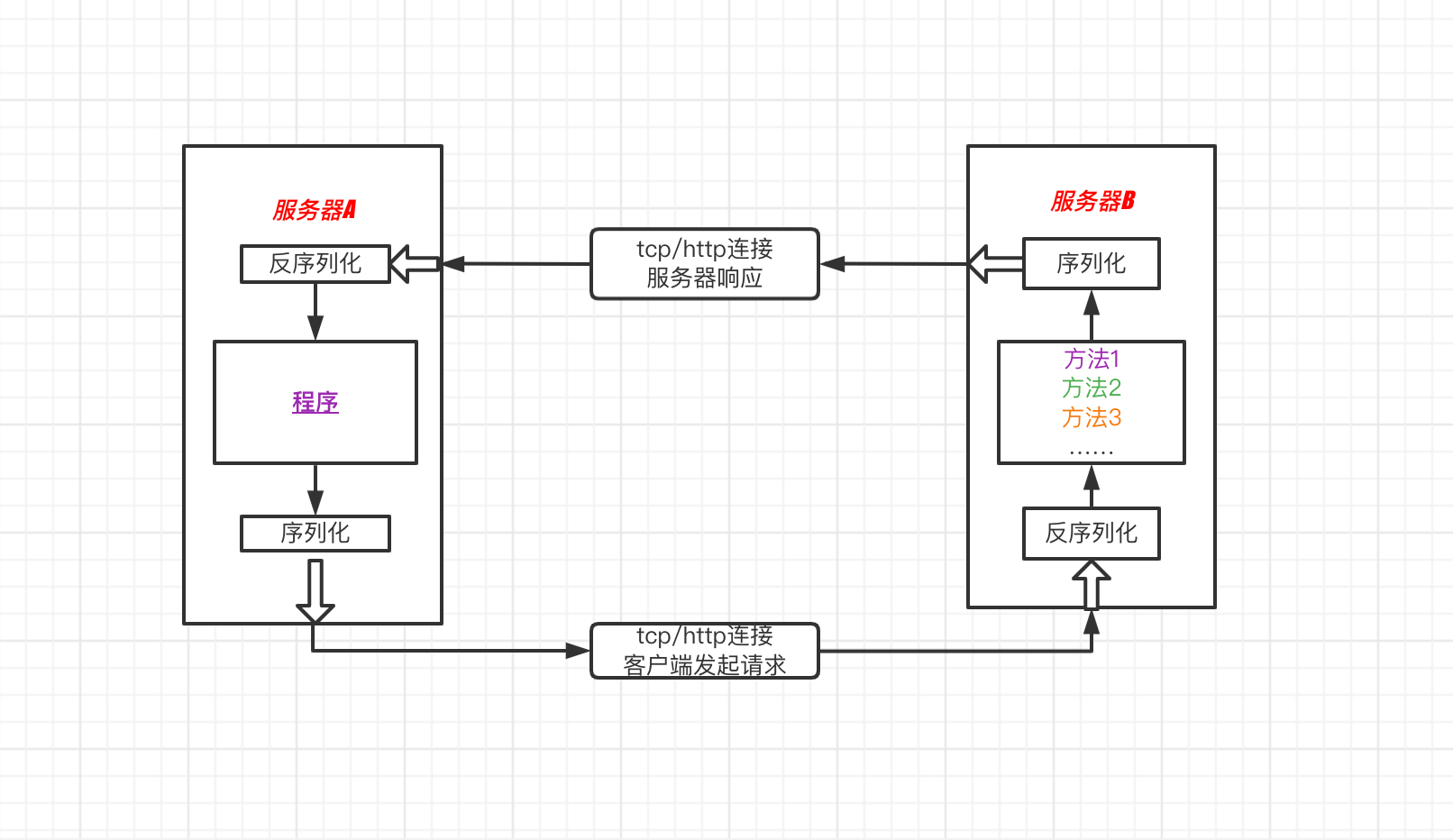

- Understanding of RPC core concepts

- Self use learning notes - connectingstring configuration

- Summary of common websites

- About stream flow, write it down briefly------

- SPC introduction

- Paging SQL

- 手写事件发布订阅框架

- Shell - introduction, variables, and basic syntax

- Use between nodejs modules

猜你喜欢

Shell脚本——Shell编程规范及变量

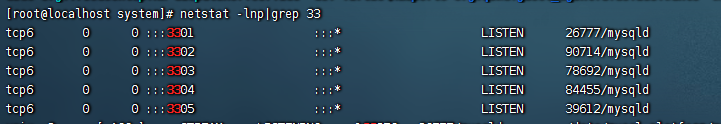

CentOS MySQL multi instance deployment

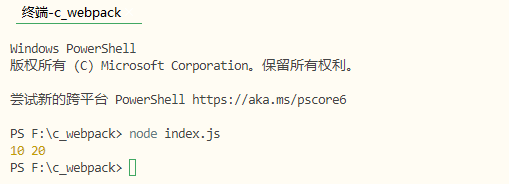

1-1 NodeJS

2.Electron之HelloWorld

1-4 configuration executable script of nodejs installation

Change the password after installing MySQL in Linux

【生活中的逻辑谬误】稻草人谬误和无力反驳不算证明

RPC核心概念理解

Milvus 2.0 détails du système d'assurance de la qualité

Detailed explanation of C webpai route

随机推荐

tidb-server 的配置文件在哪里?

Sub database and sub table & shardingsphere

Go language RPC communication

Net standard

Generation of barcode and QR code

Further optimize Baidu map data visualization

How does matlab draw the curve of known formula and how does excel draw the function curve image?

Understanding of RPC core concepts

JS to find the character that appears three times in the string

[logical fallacy in life] Scarecrow fallacy and inability to refute are not proof

Document operation II (5000 word summary)

Use of Shell sort command

[C] thoroughly understand the deep copy

Nacos + aspnetcore + Ocelot actual combat code

ASP. NET CORE3. 1. Solution to login failure after identity registers users

Simulation of infrared wireless communication based on 51 single chip microcomputer

About stream flow, write it down briefly------

Using quartz under. Net core -- operation transfer parameters of [3] operation and trigger

MySQL modify master database

El cascade and El select click elsewhere to make the drop-down box disappear